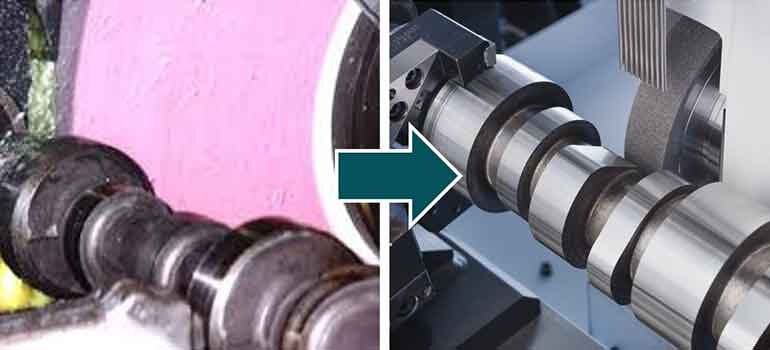

5 Reasons to Upgrade from Conventional to Vitrified CBN Grinding

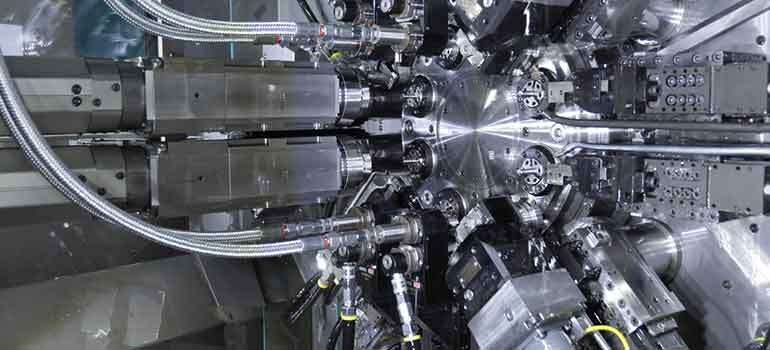

CBN, which stands for Cubic Boron Nitride, has revolutionized the machining sector ever since it’s invention. While you upgrade your conventional grinding wheels like vitrified Al2O3 or ceramic wheel to vitrified CBN, or vit-CBN, there are a few major points you should keep in mind.