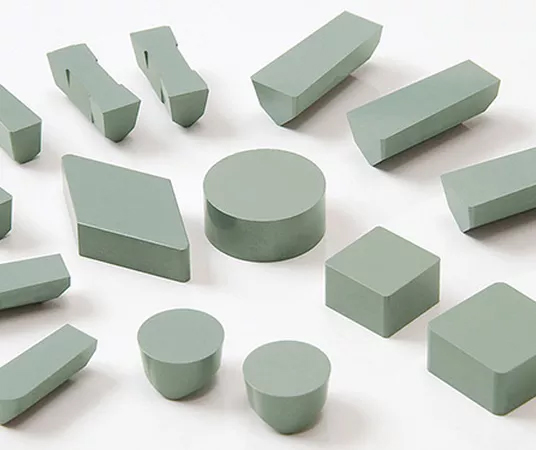

CBN Inserts

With years of experience, our staff has the capabilities and expertise to take your business to the next level. At KLANG INDIA, we combine our insights and skills to transform your processes and strategies, and in turn, your company. We’re proud to help shape and improve how our clients structure and manage their business.

Ceramic Inserts

Our premium ceramic grades ensure higher productivity. All of the grades show superior high temperature hardness, heat resistance and chemical stability. We offer many types of ceramic cutting tool materials (silicon nitride-based, alumina-based and whisker-based) in a variety of geometries to meet customer demands.

Carbide Inserts

These material grades use WC micro-grain carbide, the hard layer of which is granulated to a micro size 1μm as the substrate. Furthermore, the substrate is coated by the PVD method with TiN, TiCN, and/or TiAlN. The end results are materials that are suitable for precision machining and machining of difficult-to-cut materials. Inserts in these grades are tougher and harder than carbide and come with precision sharp cutting edges. They even have superior toughness and sharper cutting edges than ultra micro-grain carbide grades, with excellent wear resistance and thermal crack resistance.

PCD Inserts

We offers a complete range of high quality Polycrystalline diamond/PCD Inserts for machining nonferrous materials. These Inserts are designed to provide significantly increased tool life, consistent surface finish and dimensional control. As a direct result, over all cost of the component can be significantly decreased, resulting in higher productivity as well as cost savings in the total manufacturing operation are successfully achieved.

Bidemics Inserts

Bidemics’ superior physical properties compared to Whisker ceramic enable you to increase speeds; potentially as much as 2X Whisker ceramic speeds on Nickel-based Heat Resistant Superalloys (HRSA); increasing productivity and potentially offsetting the need for additional equipment to meet increasing demands. Its combination of High Hardness, Superior Thermal Conductivity and Improved Strength compared to Whisker ceramics results in significantly longer tool life when applied at typical Whisker ceramic speeds, feeds, and depth of cut. It also provides workpiece finish that is far superior than CBN or Carbide.